Understanding Dielines: The Blueprint for Custom Packaging Design.

Understanding Dielines: The Blueprint for Custom Packaging Design.

In the world of custom packaging design, the dieline is an essential element that serves as the blueprint for your box. Whether you’re creating a standard shipping box or a unique product package, getting the dieline right is key to ensuring your design prints correctly and your box functions as intended. So, what exactly is a dieline, and why is it so important?

What is a Dieline?

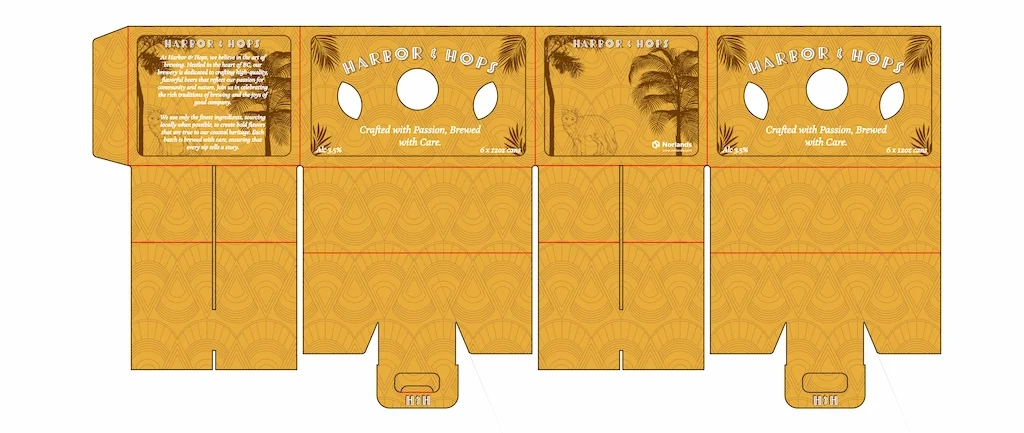

A dieline is a flat, 2D diagram that outlines the exact shape, size, and cut lines of your packaging when it’s unfolded. Think of it as the skeleton of your box—it shows where the cuts, folds, and glue points will be once the design is assembled. When designing custom boxes, the dieline acts as your guide to ensure the artwork fits perfectly within the packaging structure.

Dielines are created by packaging engineers or designers and are typically provided in vector file formats such as ArtiosCAD or PDF. They include not only the outer box shape but also indicators for:

- Cut lines: Where the box will be cut out from the

- Crease lines: Where the box will be

- Bleed areas: Extensions of your artwork that go beyond the cut lines to ensure no white edges appear during production.

- Glue tabs: Where the box will be glued

Why Dielines Matter

If you’re designing custom packaging, especially for digital printing, the dieline ensures that your artwork is placed in the correct areas so the final product looks professional and functions well. Without a proper dieline, your box may not fold correctly, or crucial design elements could end up in the wrong place, leading to costly reprints.

A well-made dieline helps:

- Ensure proper alignment of artwork and

- Avoid design errors like placing logos over folds or glue

- Guarantee a smooth production process, preventing costly mistakes during printing and

How to Use a Dieline

Once you have your dieline, it’s time to place your design onto the template. Here’s how to make the most of it:

- Design within the guidelines: Make sure important information like logos, text, and images are inside the safe zones, avoiding the edges or glue areas.

- Extend the bleed: Always extend the artwork slightly beyond the cut lines to the bleed area. This ensures there are no unwanted white edges after the box is cut.

- Check folds and creases: Review how your design will look once the box is For instance, if your logo crosses a fold line, it could become distorted.

- Test with a prototype: After completing your design, print a physical prototype using the dieline to ensure everything aligns and folds correctly.

Linking It All Together: From Dieline to Final Box

Understanding and correctly using dielines is an essential step in custom packaging box design, especially when working with digital print technology. Digital printing allows for precise, vibrant results, but to achieve a professional finish, you need a well-constructed dieline to guide the process.

For more on designing custom packaging boxes, check out our post on How to Design Custom Packaging Boxes for Digital Print to learn how digital printing can elevate your packaging design.

By mastering dielines, you can ensure your packaging design comes to life exactly as envisioned, ready for the world to see and admire.

Our Norlands Dieline: Precision, Emotion, and Simplicity Aligned

At Norlands, we don’t just use dielines; we design them as a reflection of who we are. Our dieline is not merely a structural template; it’s a silent architect that shapes the entire brand experience from the inside out. Every fold, panel, and margin has been purposefully crafted to support a clean, minimal aesthetic while maximizing production efficiency.

We’ve engineered our dieline to allow design elements to breathe, ensuring consistent alignment, seamless batch production, and effortless interaction. Whether printed digitally or traditionally, the Norlands dieline preserves balance and clarity, an embodiment of our Scandinavian design philosophy. It is this invisible structure that brings out the visible beauty of our packaging. From dieline to shelf, we believe structure is where elegance begins.

Conclusion:

Why Dielines Are the Foundation of Great Packaging

A well-designed dieline is far more than a technical file; it’s the blueprint that determines the success of every custom packaging project. From ensuring accurate folds and structural integrity to supporting high-resolution design elements, dielines are essential for a smooth transition from concept to shelf.

At Norlands, our dieline philosophy stands as proof of this principle. By integrating emotional intelligence, structural precision, and visual harmony, our dieline not only supports production, it elevates brand identity. Whether you’re a brand owner, designer, or packaging supplier, understanding and investing in thoughtful dieline creation is the first step toward packaging that is not only functional but unforgettable.

Let your packaging structure carry your story just as we do at Norlands.